WHAT WE OFFER

Bringing your visionto life

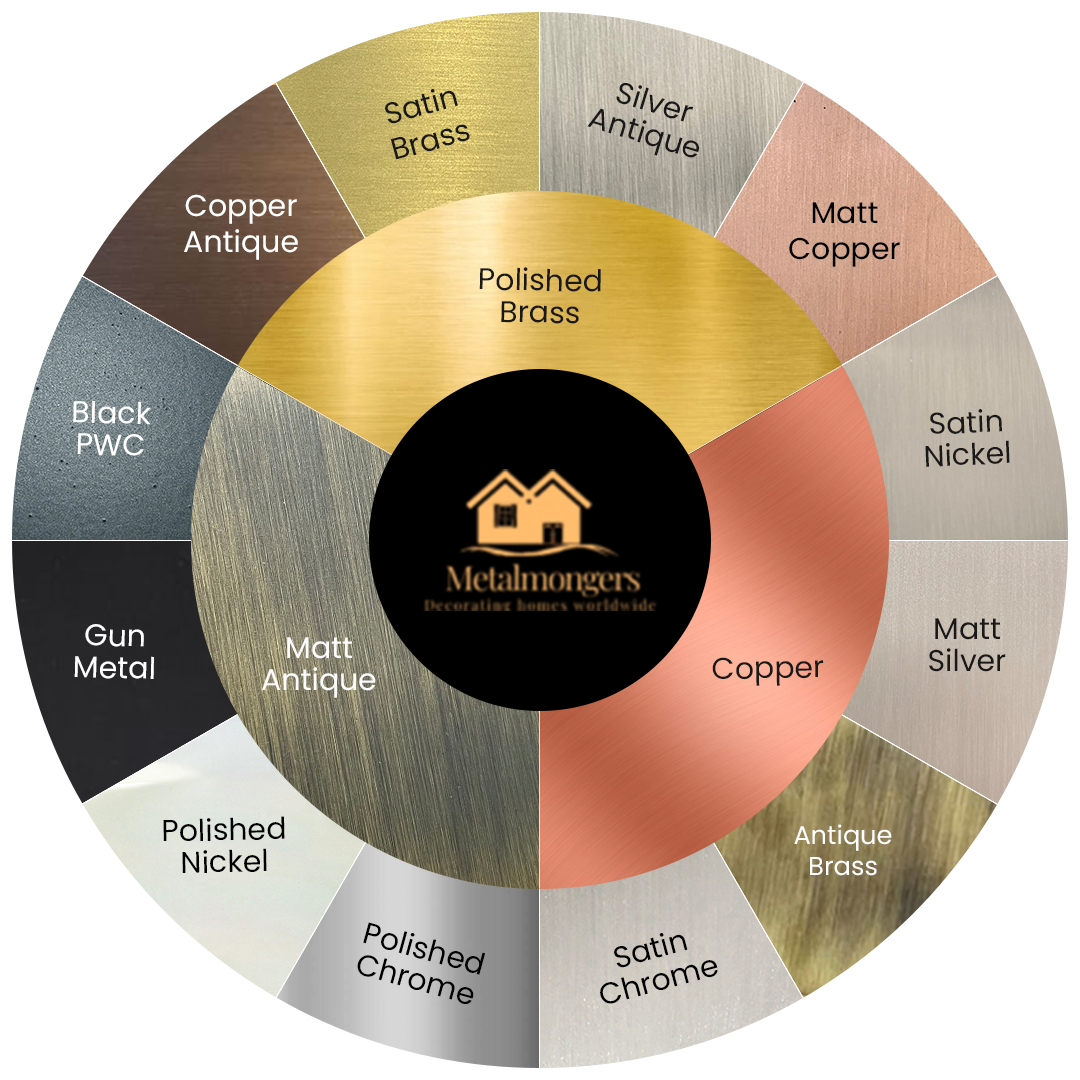

Our team boasts decades of experience in every facet of metal fabrication, from concept development and material selection to cutting-edge machining and meticulous finishing. We have the know-how to tackle even the most complex challenges, ensuring your project not only meets your specifications but exceeds your expectations.

Call Us WhatsappServices We Offer

INNOVATION

Product Design and Development

Collaborative design services to create customized metal hardware products. Prototyping and testing to ensure the functionality and durability of the designed products.

.png)